You can easily adapt Paledo to your specific needs due to its modular design. Thanks to its modern architecture, it can also be easily expanded for special applications. A configurable interface framework enables the connection to existing ERP or other third party systems with real-time data synchronization.

Cross-platform mobile concepts – offline and online – increase efficiency and improve quality.

Paledo modules at a glance

Shift and resource planning

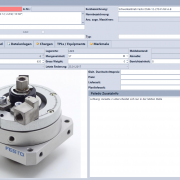

Spare parts management

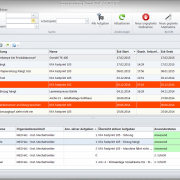

Maintenance and inspection

- Order cockpit offers a clear display of open jobs

- Automatic update in case of changes

- Take absences into account when planning available employees

- Management of company training courses

- Intuitive search and display functions with integrated master data, photos and inventories

- Spare parts reservation also on mobile devices

- Full SAP integration

- Organization of warehouse and picking processes

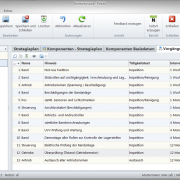

- Planning of cyclically recurring measures

- Support of time intervals (e.g. maintenance every 12 months) and consumption intervals

- Consideration of machine downtimes, public holidays, company vacations, etc. when calculating dates

Fault and repair

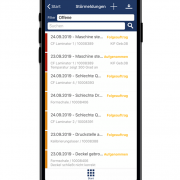

Mobile applications

Analysis and reporting

- Easy input via terminals, desktop PCs, web interface or mobile devices

- Automatic update on changes

- Innovative input technologies depending on the end device e.g..: Handwriting recognition, finger operation, RFID, barcode and camera

- Automatic feedback into ERP systems (e.g. SAP PM)

- Mobile completion of documentation documents, recording of fault and time messages, order feedback

- Mobile availability of technical documentation and plant history

- Support of video and augmented reality applications

- Cross-platform: Windows, Android and iOS

- Powerful analysis and reporting module with integrated wizard

- Conversion of filtered data into meaningful diagrams

- Simple KPI analysis for continuous improvement

- Data from connected systems (e.g. SAP) can be seamlessly included in the analyses