Integrate the production through machine operator maintenance and joint planning processes

With official requirements, occupational safety regulations and manufacturers’ warranty conditions, the demands on maintenance documentation are constantly increasing. Non-compliance often represents a violation of the plant operator’s duty of care and, in the worst case, has financial and legal consequences. Paledo offers an efficient, user-friendly solution to meet these requirements. In addition, Paledo offers numerous additional functions that support the work of the maintenance engineer in addition to the creation of documentation.

Functions of Paledo for maintenance and inspection

- Mobile offline / online provision of maintenance data, also from connected ERP systems (e.g. SAP PM)

- On-site data capture on mobile devices with innovative input technologies such as handwriting recognition and finger operation

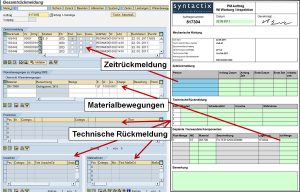

- Automatic order post-processing (such as generation of follow-up actions in case of deviations, technical and time feedback in the ERP system)

Work preparation & quality assurance

The administration of documentation templates with Word and Excel as well as the necessary quality assurance is usually a time-consuming, error-prone, manual activity. Paledo supports the work preparation with a modular designer for the creation and quality assurance of maintenance documents. Existing documents from Word, Excel and PDF can be easily imported and reused. In addition, Paledo creates the documentation automatically from the plant structure. The powerful documentation tool enables the maintenance of complex documents without programming activities.

Mobile access and data collection

With Paledo, the mechanic receives an intuitive system that provides him with all relevant data, such as order, message and system data, either offline or online. Thus, bad connections or dead spots do not pose a problem. In addition, the installer has access to the digital knowledge database with manuals, sectional drawings, circuit diagrams, etc., up to measuring points and the component’s life cycle. In addition to the mobile provision of information, the system is also used for data acquisition. In addition to the classic, mask-based recording, Paledo offers the possibility to display maintenance documents in the style of established paper forms. The technicians fill in their known documents comfortably with pen-finger operation on the tablet PC and can take photos, read RFID and barcodes. The manual selection of data and manual assignment of photos is no longer necessary. Catalogs, automatic input validation and linked work instructions facilitate input and avoid tedious post-processing. Immediately after the work is completed, the data is available at the company headquarters. Paledo automatically carries out all actions for order post-processing, such as technical feedback to SAP, booking of spare parts and time feedback.

Automatic editing

Compared to paper-based processes, the digital capture of data on site with Paledo offers numerous possibilities for automatic post-processing – the flexibility that Paledo offers the customer is amazing. In no time at all, rules can be defined for the automatic creation of fault messages, follow-up actions or the documentation of exchange of plant inventory. Clearly arranged cockpit functions draw attention to relevant information by, for example, highlighting limit value violations and other deviations and automatically escalating them if required.